[Image from Unsplash]

By Anmol Shrivastava and Indrajit Gupta

Recap of Part 2:

The AAIB team has moved swiftly. While the search for a formal head of the investigation continues, they’ve already secured the chaotic crash site, enlisted international aviation safety experts, begun documenting the wreckage, and are closely examining fuel records, maintenance logs, crew history, environmental conditions, and black box data. Their ultimate goal: to triangulate these insights and uncover the deeper “why” behind the Boeing 787’s unprecedented crash.

♦¤♦¤♦¤♦

Even after investigators confirm key details—whether the RAT deployed, the landing gear remained down, or how much runway was used—these are only pieces of the puzzle, not the full picture.

Knowing what happened is just the start. The real challenge is understanding why it happened—what hidden technical, mechanical, or human factors led to the disaster.

At this stage, investigators develop multiple hypotheses to explain how various failures may have unfolded together. These aren’t guesses—they’re evidence-based theories built from data, expertise, and a deep understanding of aircraft systems.

- One possible chain: Both engines lost power—cutting off electrical generation—triggering RAT deployment, followed by the aircraft’s loss of lift and rapid descent. But if that’s true, why did both engines fail? Was it contaminated fuel? A mechanical failure in both engines? Or did something external, like debris ingestion or bird strike, compromise them simultaneously?

- Another possible chain: There was no total engine failure at first, but a hidden electrical fault knocked out power to key systems—triggering the RAT. That electrical loss may have disabled cockpit instruments, reduced engine control, and degraded aircraft performance, explaining the abnormal climb and descent profile.

- Or perhaps a deeper, layered chain: A sensor malfunction provided false data to the engine control system, leading to reduced thrust output, which the pilots couldn’t easily detect due to other system warnings. As performance dropped, the aircraft couldn’t climb, electrical demand exceeded supply, the RAT deployed, and the situation rapidly spiraled beyond recovery.

- Another possible chain: A single engine suffered a hidden failure or partial thrust loss just after V1—the point of no return on the runway. Committed to takeoff, the aircraft lifted off with asymmetric power, which can severely impact directional control and climb performance. If this was compounded by other factors—such as inaccurate sensor readings, undetected fuel contamination, or excessive aircraft weight—the degraded thrust margins may not have been immediately obvious to the crew. Under stress, with limited time to react, human factors come into play: misinterpreted instruments, incomplete situational awareness, or incorrect assumptions about aircraft performance. As the flight continued with compromised thrust and strained systems, electrical output may have fallen below demand, triggering the RAT and setting off a cascading sequence that the crew could not recover from.

The landing gear remaining extended fits into these chains too—not as a standalone clue, but as another consequence. Were the pilots dealing with cascading failures and deprioritized gear retraction? Or did a hydraulic fault earlier in the chain prevent retraction altogether, adding drag and worsening the aircraft’s inability to climb?

No single clue—not the RAT, not the landing gear, not the shallow climb—explains AI 171 in isolation. The truth lies in connecting these events in the right sequence, proving how one failure triggered the next, and how a series of small problems escalated into catastrophe.

Every scenario investigators explore isn’t about isolated guesses—it’s about building complete chains of cause and effect

That’s why every scenario investigators explore isn’t about isolated guesses—it’s about building complete chains of cause and effect, then testing whether those chains hold up against real data, physical evidence, and system logic.

[AI generated image]

Testing Theories Through Simulation

Once investigators develop possible failure scenarios, the next step is to test which ones hold up under real-world conditions. That’s where high-fidelity simulators—like those used to train pilots for emergencies—become essential.

Simulators have become a cornerstone of modern crash investigations. One of the most famous examples is the “Miracle on the Hudson.” While Captain Sully was hailed for safely ditching his Airbus A320 in the Hudson River after a dual engine failure, some initially questioned whether he could have turned back to an airport. Early simulations suggested it was possible. To complicate matters, ACARS data initially indicated the engines were still “sub-idle,” implying partial thrust. But once a realistic 35-second human reaction time was factored in and full flight data was analyzed, it became clear: both engines had failed after bird strikes, and a water landing was the only survivable option.

[Simulations attempt to recreate the events of Captain Sully’s crash landing — a scene from the 2016 film Sully: Miracle on the Hudson]

Similarly, investigators will now recreate AI 171’s final moments in a simulator, inputting every known variable—aircraft weight, weather, flap settings, engine performance, and system status at each point in the flight.

They will run multiple scenarios: a single engine failure, both engines losing power, or a cascading systems failure. Each will be tested against known data—flight path, radar returns, and video evidence—to determine which chain of events best matches the aircraft’s actual behavior.

These simulations are not one-off events. Each run often raises new questions. If the simulator shows that a particular failure chain could explain the shallow climb, investigators will look deeper—was there evidence in the wreckage to support that scenario?

If the simulations suggest the aircraft behaved in a way that doesn’t match the black box data, investigators must revisit their theories, gather more evidence, and adjust their approach.

Gathering More Evidence as the Investigation Evolves

Crash investigations don’t follow a straight line. Data collection and analysis move in tandem, often looping back as new questions emerge—more a dance than a sequence.

If investigators suspect, for example, that the aircraft was overloaded at takeoff, they won’t rely solely on airline-provided manifests. With much of the wreckage burned or destroyed, physical verification is often impossible. Instead, they may analyze airport CCTV footage—tracking how the aircraft was loaded, watching boarding patterns, cargo movements, or the number of baggage containers. In some cases, they’ll reconstruct the likely takeoff weight using video evidence, ground handling logs, or witness accounts.

Engine teardowns may follow, with investigators examining turbine blades, compressors, and fuel systems for signs of internal failure, debris damage, or metal fatigue. Any anomalies feed directly into the next round of simulations.

They may also return to the crash site, searching for overlooked fragments that gain relevance as theories evolve. Specific components—such as flight control actuators, landing gear mechanisms, pitot tubes, or angle-of-attack sensors—will undergo close inspection to identify mechanical faults or malfunctions that may have triggered or compounded the failure chain.

Interviews with maintenance crews, pilots, and technical staff may continue as well. Investigators will review service records, previous inspections, and any maintenance history that could shed light on hidden issues building up over time.

The process is like peeling back the layers of an onion. Each discovery prompts new questions, new tests, and fresh angles of investigation.

Debate and Red Teaming

Within the investigation team, technical experts from diverse fields rigorously debate each theory. They challenge one another’s assumptions, hunting for weak links, overlooked details, or contradictions in the working hypotheses.

This process is designed to counter groupthink. Every idea must be tested, questioned, and defended from multiple angles. Pilots, engineers, system designers, and human factors specialists each bring unique perspectives, and this internal push-and-pull helps refine the most credible explanations while discarding weaker ones.

Ironically, even teams studying human error aren’t immune to human dynamics. Disagreements happen. One veteran investigator recalled a case where a frustrated team member skipped a key meeting. “But we eventually brought him back,” he said with a laugh. “Managing those moments is part of the job. You can’t investigate cockpit breakdowns while having your own. It’s up to the lead investigator to guide the team through conflict, ensure every voice is heard, and arrive at a sound, defensible conclusion.”

Narrowing Down the Probable Cause

As the investigation advances, weaker scenarios are ruled out and stronger ones are refined through simulations, data analysis, physical inspections, and repeated testing.

Investigators work through a process of elimination—gradually narrowing the field until one sequence of events emerges as the most consistent with all available evidence: digital, physical, technical, and human.

Only then do they identify the probable cause—the most likely, evidence-based explanation for why AI 171 crashed. Alongside it, they also flag contributing factors—issues that didn’t directly cause the crash but worsened the situation or hindered recovery. These might include weak warning systems, missed maintenance, design flaws, or training gaps.

Ultimately, each layer of insight brings investigators closer to the real objective: understanding what went wrong—and how to prevent it from happening again.

Interim Safety Actions and the Report

Once investigators have pieced together the full sequence of events, tested every theory, and narrowed down the most likely explanations, they prepare a detailed draft report. This document doesn’t just summarize the accident—it reconstructs it in painstaking detail, including a timeline of the flight, technical analysis of the failures, the sequence of events, and the investigation team’s conclusions about what went wrong and how it can be prevented from happening again.

But writing the report isn’t just about telling the story accurately—it also has to be legally watertight. Air crash reports become part of the global public record. They are scrutinized by governments, manufacturers, regulators, legal teams, insurance companies, and sometimes, victims’ families pursuing justice or compensation—even though ICAO guidelines clearly state that investigation reports are intended to improve safety, not assign blame or be used for legal proceedings. Every conclusion must be backed by hard evidence, validated tests, and clear logic.

That’s why the review process for the draft report is so rigorous. Before the report is finalized, accredited representatives from other countries involved in the investigation—like the aircraft’s country of design, the engine manufacturer’s country, and others—are invited to review the draft. In the case of AI 171, technical experts from the United States, Boeing, GE, and other key stakeholders will likely participate in this process, given their connection to the aircraft and its systems.

These external parties can suggest corrections, flag missing information, or provide technical clarifications, but they cannot override the investigation’s final conclusions. They are typically provided sixty days as per Rule 14(2) to send in their observations.

Once all feedback is considered, the final report is published. It provides a complete, transparent account of the disaster—including the technical findings, the probable cause, contributing factors, and most importantly, a set of safety recommendations designed to prevent similar tragedies in the future.

That said, there are already questions swirling over whether India will release a preliminary report for AI 171. Normally, ICAO standards require a basic report within 30 days, summarizing key facts—but not conclusions. In some cases multiple preliminary reports have also been issued.

In this case, with multiple complex failures suspected, some insiders are doubtful about how much clarity a rushed preliminary report could offer.

As one veteran investigator put it bluntly, "I’ve been part of three major crash investigations, and I don’t think we ever released a preliminary report. We only do that when there isn’t an iota of doubt. Because once we do, and later evidence points elsewhere, it’s egg on our face. The approach depends entirely on the context and is at the discretion of the lead investigator."

In practice, what often happens is more nuanced. If investigators identify a potential safety risk—even without firm conclusions—they discreetly coordinate with concerned parties like the aircraft manufacturer, engine maker, or airlines to initiate precautionary measures. This could include technical inspections, troubleshooting exercises, temporary operational restrictions, or issuing general advisories. The focus is on mitigating immediate risks and identifying hidden flaws that could jeopardize other aircraft in service. These steps are deliberately kept independent of the official investigation timeline, ensuring investigators aren’t boxed into premature conclusions while still addressing urgent safety concerns in real time.

Publication of the Report

Under India’s Aircraft (Investigation of Accidents and Incidents) Rules, 2017, the Aircraft Accident Investigation Bureau (AAIB) is responsible for publishing the final crash report once the investigation is complete, as outlined in Rule 14(3).

In past cases, India has released detailed reports—including technical findings and safety recommendations—typically published in English to ensure accessibility for the global aviation community. These reports are made available on the AAIB or Ministry of Civil Aviation websites and shared with ICAO, foreign regulators, and relevant aircraft manufacturers.

However, not all information enters the public domain. Rule 17 allows for redaction of sensitive material—such as cockpit voice recordings, personal identifiers, or security-related technical data—to protect privacy and maintain safety integrity. The published report focuses on key evidence, the sequence of events, root causes, and recommended corrective actions.

The primary goal is not to assign blame, but to identify root causes and prevent recurrence

Unlike countries such as the United States—where major crash investigations often include public hearings with expert testimony—India’s process is typically closed-door. The final report is usually the first full public disclosure. The only exception is when the government orders a Court of Inquiry under Rule 12, a quasi-judicial public process, now rarely used since AAIB assumed responsibility in 2012. The rationale is clear: the primary goal is not to assign blame, but to identify root causes and prevent recurrence. Still, the government retains the authority to initiate a public inquiry if warranted.

In high-profile cases like AI 171, the key question remains: Will the public see a detailed, transparent technical report explaining what happened—and how aviation safety will improve as a result? Only time will tell how much is ultimately revealed.

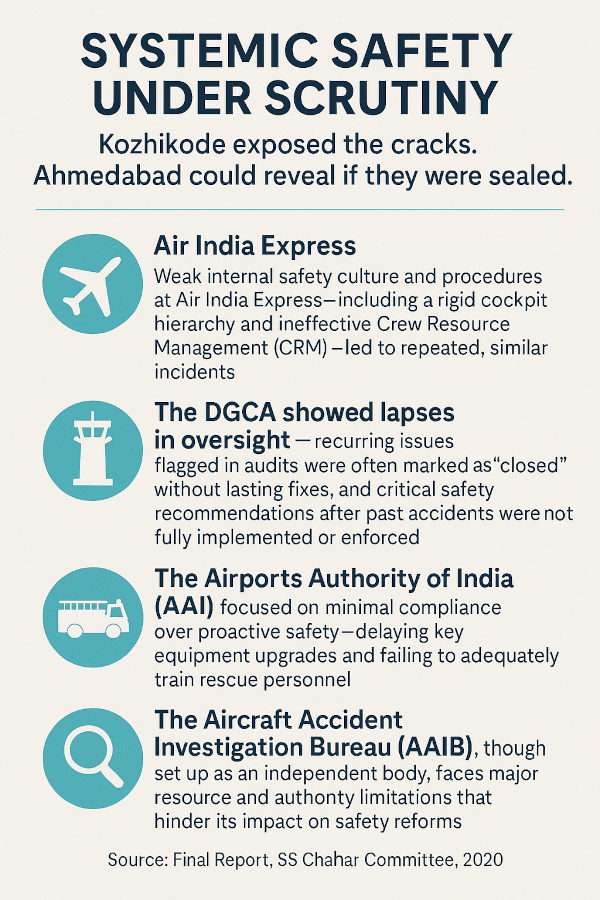

So far, India’s response to air accident investigations has been largely reactive. Until 2021, the Chahar Committee reported that the Aircraft Accident Investigation Bureau (AAIB) had completed 150 investigations—but, due to manpower shortages, had not conducted a single proactive safety study, despite that being a core part of its mandate.

On June 14, the Ministry of Civil Aviation announced the formation of a second high-level committee, chaired by Union Home Secretary Govind Mohan, which held its first meeting in Delhi. The multi-disciplinary committee includes the Civil Aviation Secretary, senior officials from the Home Ministry, Gujarat’s Home Department and State Disaster Response Authority, the Ahmedabad Police Commissioner, the Director General of Inspection and Safety (Indian Air Force), and the Director General of the Bureau of Civil Aviation Security.

This high-powered committee will run in parallel to the AAIB’s crash investigation. It is expected to submit its report within three months, with a focus on formulating Standard Operating Procedures (SOPs) to prevent similar incidents in the future.

Meanwhile, the Parliamentary Standing Committee on Transport, chaired by JDU MP Sanjay Jha, has summoned the Civil Aviation Secretary, officials from Boeing, DGCA, and Air India for a detailed briefing.

The moot point: Will this heightened scrutiny finally lead to a stronger, more proactive air safety culture?

When the Impossible Happens: Why AI 171 Defies Simple Explanations

Statistically, a fatal air crash is almost unthinkable. If you flew every day, it would take nearly 100,000 years to be in a fatal accident. You’re far more likely to be injured on the drive to the airport than during the flight itself.

But statistics offer little comfort once you're in the air. Turbulence rattles nerves more than potholes ever could.

For a crash to occur, it typically takes a rare and deadly chain of events

Modern aircraft aren’t just built to fly—they’re engineered not to fail. Every conceivable fault is anticipated. Layers of redundancy guard against human error, technical glitches, and even bad luck. If a pilot forgets to set the flaps, the aircraft blares warnings. If that alarm fails, engines still power through. The design assumes one fault—maybe two—but never a total system collapse.

Because for a crash to occur, it typically takes a rare and deadly chain of events—cascading failures, each defeating the next backup, all aligning in perfect, catastrophic timing.

That’s why, even as social media buzzes with theories—fuel contamination, software glitches, twin engine failure, incorrect flap settings—seasoned investigators are cautious. In a system built on redundancy, no single failure should bring an aircraft down.

AI 171 is especially baffling—because of when it happened, and how it looked.

A Dreamliner falling from the sky moments after liftoff? That defies everything pilots, engineers, and regulators plan for

The aircraft plunged seconds after takeoff—when engine thrust is at maximum, lift is strongest, and procedures are most tightly controlled. Takeoff is sacred in modern aviation. Crashes at cruising altitude are rare. But a Dreamliner falling from the sky moments after liftoff? That defies everything pilots, engineers, and regulators plan for.

As the retired Air Marshal quoted earlier noted: “Captain Sully was rightly hailed for the Hudson River landing—he had the luxury of altitude. Back in the Air Force, we considered the Sabarmati a possible emergency landing site for engine-out drills in that area. Had this aircraft gained more height, maybe they could’ve attempted a ditching. But at just a few hundred feet? Without altitude or clear ground ahead, recovery is almost impossible.”

“The 787’s electrical system is strong enough to power a small town. What we’re seeing isn’t a normal failure. It’s something much bigger.”

Grainy video footage shows the aircraft struggling to climb, then descending in a disturbingly flat, shallow arc—an unnatural trajectory for an aircraft of this size and power. To experienced aviators, it suggested not a gradual failure, but a sudden and catastrophic loss of thrust or control.

A senior engineer who helped induct the Dreamliner into Air India’s fleet in 2012 said: “The 787’s electrical system is strong enough to power a small town. What we’re seeing isn’t a normal failure. It’s something much bigger.”

The timing—takeoff, full power, low altitude—makes AI 171 a crash that defies conventional explanations. Even veteran crash investigators are calling it “the rarest of the rare.”

“To my knowledge, nothing quite like this has ever happened,” Captain Kishore Chinta, a former investigator with the Aircraft Accident Investigation Bureau (AAIB), told the BBC.

The odds of a single engine failure are already low—about 1 in 375,000 flight hours, or once every 43 years of nonstop flying. The chance of both engines failing simultaneously? Approximately 1 in 140 billion flight hours—roughly once every 16 million years

One of the most alarming theories: a dual engine failure at takeoff.

Twin-engine aircraft are designed specifically to prevent this. Their engines are segregated across all critical systems—pneumatics, electrics, hydraulics—so that if one fails, the other continues to operate independently. As one veteran aviation expert put it: “They go to great lengths to ensure that if one engine fails, the other keeps running. But from the video, I strongly suspect both engines lost power. How that happened—I really don’t know.”

The odds of a single engine failure are already low—about 1 in 375,000 flight hours, or once every 43 years of nonstop flying. The chance of both engines failing simultaneously? Approximately 1 in 140 billion flight hours—roughly once every 16 million years.

In past cases, dual engine failures have been caused by bird strikes, catastrophic mechanical failures, foreign object ingestion, or critical pilot error—but rarely, if ever, without a clear trigger.

There have been reports of dual engine rollback events on Boeing 787s, such as the All Nippon Airways incident at Osaka in 2019—but that occurred during landing rollout after thrust reverser deployment, and engine failure was ultimately ruled out.

AI 171, by contrast, presents a far more troubling mystery. One that challenges not just the mechanics of the aircraft, but the very assumptions that modern aviation is built on.

If AI 171 truly experienced a simultaneous dual engine power loss, it would be almost unprecedented—and profoundly unsettling for the aviation world.

Modern air travel is built on the assumption that the two engines on a twin-engine aircraft are completely independent. This isn’t just a design feature—it’s the foundation of global aviation safety. Under ETOPS (Extended-range Twin-engine Operational Performance Standards), aircraft are certified to fly up to 180 minutes from the nearest airport—but only after proving they can safely continue flight on one engine.

That’s what allows aircraft like the Dreamliner to fly transatlantic routes, crossing oceans and remote regions far from alternate airports. The next time you board a flight from Mumbai to New York, you’re relying on that principle.

If both engines can fail together—without warning, without a bird strike, without mechanical damage, and without pilot error—it challenges the very core of aviation safety. It calls into question decades of engineering, testing, and regulatory assumptions.

The alternative? That something entirely different—and equally catastrophic—unfolded. A unique chain of failures striking at the worst possible time: takeoff, when pilots have seconds to respond, little altitude to recover, and no room for error.

In either case, the cause must be found. Because whether it reveals a hidden vulnerability in twin-engine systems or exposes a rare and dangerous failure sequence, the implications of AI 171 extend far beyond a single tragic crash.

avi on Jul 29, 2025 12:50 a.m. said

This theory deserves a look https://www.youtube.com/watch?v=fl1kUudq7Tw