[Debris at the crash site of the AI-171 flight in Ahmedabad. PM Narendra Modi visits the on June 13, 2025. (Source PIB; image cropped from original)]

By Anmol Shrivastava and Indrajit Gupta

Recap of Part One:

The first ever Boeing 787 Dreamliner crashed on June 12 in Ahmedabad shortly after take-off. The immediate, high-stakes investigation by India's AAIB has put Boeing's safety record and reputation, Air India's transformation under the Tata group, and the Indian government's oversight squarely in the global spotlight. With public trust shaken, and black box analysis underway domestically, the world watches as investigators piece together the complex puzzle of AI 171.

♦¤♦¤♦¤♦

Even as the final investigation team takes a few more days to coalesce, on June 12, the AAIB's own team, under G.V.G. Yugandhar’s leadership, had an immediate priority: secure the crash site, preserve every scrap of evidence, and begin the painstaking task of reconstructing what went wrong.

In the weeks to come, the focus will shift to connecting the dots—trying to understand how technical glitches, crew decisions, or hidden aircraft issues conspired to cause the crash. Even before the full picture emerges, if investigators uncover any serious risks—like a hidden fault that could imperil other aircraft—they can issue interim safety warnings to prevent another disaster.

Establishing the "what" is often far easier than the "why," which can take many months

The ultimate goal is to pinpoint the true cause of the crash—whether it was an aircraft problem, a flight handling error, or a fatal combination—and recommend changes to ensure it never happens again. Experts agree that establishing the "what" is often far easier than the "why," which can take many months.

Let's start at the beginning.

Securing the Crash Site: First Steps and Global Norms

Site security sounds simple on paper. In reality, it's a chaotic tightrope walk. Moments after impact, first responders surge in, battling fires and searching for survivors. Yet, these heroic rescue efforts risk disturbing the very wreckage that holds the investigation's vital clues. Balancing immediate life-saving with critical evidence preservation is a high-stakes challenge.

In the early hours after the tragedy, the crash site near Meghaninagar, Ahmedabad, was treated as a forensic crime scene. Detailed global norms, laid out by ICAO, recommend that debris be cordoned off, guards maintain round-the-clock security, and investigators work methodically—aware that even a misplaced panel or shifted wire could obscure vital clues. In major crashes, cameras often record rescue operations and early site activity, helping investigators later distinguish accident damage from rescue-related disturbances.

In Ahmedabad, law enforcement quickly cordoned off the wreckage area, especially from intrusive videographers and cameramen. The contamination of evidence is a real risk. “Camera crews were granted access to a building at a distance. The building was on fire and would have posed a huge risk to people. In fact, it continued to smolder till the next day," said a visual editor at a leading national daily.

[A screenshot from Instagram user @sahill_ke_vlogs, shows nearby residents making vlogs at the crash site and also holding the aircraft equipment]

The one major difference between a crime investigation and a crash investigation? AAIB air crash investigations—guided by ICAO’s Annex 13—are not about apportioning blame or determining liability. Their sole focus is prevention.

Aviation depends on constant learning and trust. If pilots, airlines, or engineers fear legal repercussions, they might hesitate to report near-misses, technical anomalies, or safety lapses

There’s a good reason for this approach. Aviation, by its nature, depends on constant learning and trust. If pilots, airlines, or engineers fear legal repercussions, they might hesitate to report near-misses, technical anomalies, or safety lapses. A blame-free environment fosters open reporting, candid data sharing, and cross-border cooperation. It allows investigators to trace complex failure chains without obstruction, identifying not just immediate technical flaws, but systemic issues in design, training, maintenance, or oversight.

International Reinforcements Join the Probe

Immediately after the crash, India—as the State of Occurrence—formally notified the International Civil Aviation Organization (ICAO), the State of Manufacture (the United States, for Boeing and GE engines), and the States of nationality of the passengers (the United Kingdom, Portugal, and Canada). These nations are entitled to participate in the investigation, which Indian authorities lead.

In this case, India also holds the titles of State of Registry (the aircraft’s official tail number, VT-ANB, is registered in India) and State of Operator (Air India was flying the aircraft).

While media reports—including this story—refer to the crash as AI 171, investigators use a more specific identifier: the aircraft’s registration number, VT-ANB, a Boeing 787-8 operated by Air India. Unlike flight numbers or call signs, which can vary from day to day, the registration remains constant throughout the aircraft’s service life. (After the tragedy, Air India permanently retired the flight number from service.)

By June 13, just one day after the crash, the UK’s Air Accidents Investigation Branch (AAIB) had dispatched a four-member expert team to assist. The U.S. National Transportation Safety Board (NTSB) soon followed, bolstered by the Federal Aviation Administration (FAA), Boeing, and GE Aerospace. On Friday, media reports suggested that ICAO might send its own independent observer to aid the investigation.

Collectively, these agencies bring cutting-edge tools—from forensic wreckage analysis and black box decoding to flight data modeling and insights, gleaned from Dreamliner operations worldwide.

Much of the early investigative effort is being run out of the GUJSAIL hangar within Ahmedabad Airport, now the team's temporary base.

Documenting the Wreckage: Race Against Time

Despite the scale of resources, the challenges are immense.

The wreckage is badly burned, twisted beyond recognition in parts. Looming monsoon rains threaten to wash away fragile evidence. For investigators, every hour counts—because once clues are disturbed, the sequence of failure becomes infinitely harder to trace.

"Each significant piece will be photographed and videographed before removal or being shifted, following international aviation accident protocols," a senior official at the crash site told The Times of India.

These steps aren’t random; there’s a method to this seeming madness.

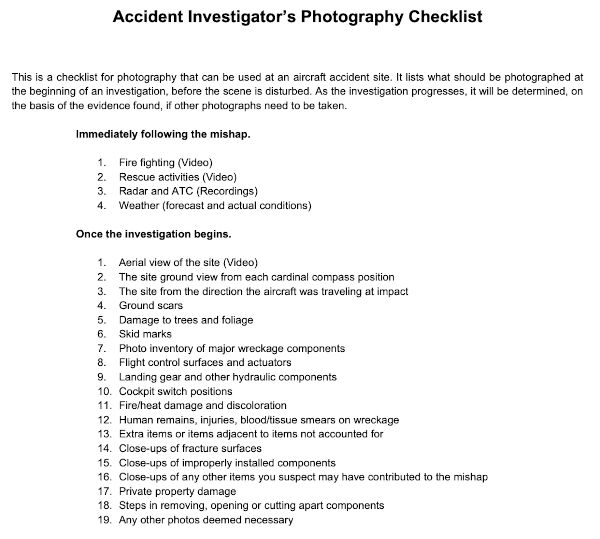

ICAO’s Manual of Aircraft Accident and Incident Investigation (Doc 9756, Part III) provides detailed checklists for documenting wreckage.

The process begins with securing perishable clues: fire patterns, ground scars, and rescue activities are documented before anything is moved. Once stabilized, wreckage is staked and tagged, aerial images are taken, and every fragment is logged using GPS, culminating in a wreckage distribution chart that maps parts scattered across the site.

[The Photography Checklist from the ICAO Aircraft Accident and Incident Investigation Manual]

"Investigators implement grid systems to accurately map the wreckage distribution and debris field. The pattern of debris is crucial for indicating the angle of impact and reconstructing the aircraft’s flight path," the TOI source elaborated.

Why this painstaking endeavor? Because debris distribution reveals far more than meets the eye. It helps investigators decode the aircraft’s breakup sequence, impact trajectory, and whether structural failures occurred mid-air or only upon impact.

In past cases, like the 1989 United Airlines Flight 232 disaster, a tiny, undetected fracture in an engine disk led to catastrophic failure. When the disk disintegrated mid-flight, it ruptured all three of the aircraft’s hydraulic systems, leaving the crew with almost no control and forcing a crash landing. Without meticulous wreckage analysis, such clues might have been missed entirely.

[Scenes from the Air India Boeing 787 crash]

But the scale of destruction poses serious obstacles. "Going by the visuals of this accident, you would appreciate that this aircraft has been very badly damaged by fire," Group Captain Aurobindo Handa (Retd), former AAIB Director General, told PTI. "Therefore, corroborating and stitching together the evidence would be a tedious process. In all probability and in fairness, the investigation is likely to be a long-drawn process."

A chemical analysis of key wreckage components is underway to check for abnormal contaminant levels. An officer familiar with the probe told The Indian Express, "Since the explosion and subsequent fire have damaged much of the aircraft, especially the fuel tanks, forensic engineers of the investigating team have gathered as much relevant debris as possible to find traces of elements that could indicate if there had been fuel contamination."

By June 22, heavy trucks began carefully transporting major wreckage from the crash site to the GUJSAIL hangar at Ahmedabad Airport. There, shielded from the elements, investigators can methodically reconstruct the debris—like assembling a giant 3D puzzle—to determine impact angles, flight paths, and possible failure points.

Transporting the wreckage hasn’t gone entirely to plan.

On June 22, a truck carrying the aircraft’s vertical stabilizer—or tail fin—got stuck under a tree branch near the Anti Corruption Bureau (ACB) office on Airport Road in Ahmedabad, blocking traffic for nearly an hour. Images of the stranded tail fin sparked fresh questions over logistics and site handling.

[Air India crash probe: as the wreckage is moved, the tail section gets stuck enroute in Ahmedabad]

There have been other concerns too. On Wednesday, The Economic Times reported that both the aircraft’s refuelling bowser operated by Adani Airports and the fuel tanker were supposed to be sealed after the crash, with fuel samples sent to multiple independent labs—standard protocol when engine failure is suspected. But confusion between the AAIB and DGCA over which agency was responsible for sealing the fuel, meant the samples reportedly went only to Indian Oil’s lab, deviating from global best practices. Investigators and experts say this kind of misstep can delay the process and undermine one of the earliest opportunities to detect issues like fuel contamination—especially in a case where both engines may have lost power so soon after takeoff.

This raises fresh questions, coming just days after police uncovered a major racket siphoning off thousands of litres of aircraft fuel meant for Delhi airport—seized in Mundka, West Delhi. That syndicate exposed serious vulnerabilities in how aviation fuel is handled, raising concerns about possible contamination, diversion, or inaccurate reporting. Such risks carry direct safety implications, especially when flights operate between major hubs like Delhi and Ahmedabad.

That said, there’s no direct evidence linking these theft cases to AI 171’s crash. Investigators can’t assume a connection, but they will likely examine whether fuel batch integrity was maintained across every leg of the aircraft’s journey, including refueling at both Ahmedabad and Delhi. Any leakage, tampering, or compromised sealing along the supply chain could become a critical factor.

Such lapses add layers of complexity to an already difficult investigation.

Nevertheless, preliminary assessments would likely have begun yielding initial clues. Experts would be examining the engine fan blades for rotation damage—bent blades typically indicate the engine was turning at impact, while intact blades might suggest a loss of thrust. Investigators would also be scrutinizing landing gear and flap positions: Were they extended? Retracted? Jammed? Each detail inches them closer to understanding the aircraft’s final moments.

Weather and Environmental Factors

Despite clear skies, investigators will be meticulously analyzing the weather and runway conditions at the time of the crash. Perishable environmental data must be captured immediately, before shifting weather, aircraft movement, or human activity obscure critical clues.

Ahmedabad’s temperature was reportedly around 40°C during takeoff—extreme heat that can marginally reduce engine thrust and aerodynamic lift, though typically not to catastrophic levels. However, precise tarmac and runway temperatures have not been officially disclosed.

In parallel, data from METARs (real-time airport weather reports), weather radar, airport sensors, and CCTV footage would be reviewed for microbursts, wind shear, or rapid temperature fluctuations that could have affected aircraft performance. Even subtle disruptions have played a role in past disasters—such as Delta Air Lines Flight 191, which crashed on approach in 1985 due to an undetected microburst. Microbursts are sudden, violent downdrafts of air that can slam into aircraft during takeoff or landing, drastically reducing lift. Globally, microbursts have been linked to at least a dozen major crashes, often catching flight crews off guard due to their short-lived and highly localized nature.

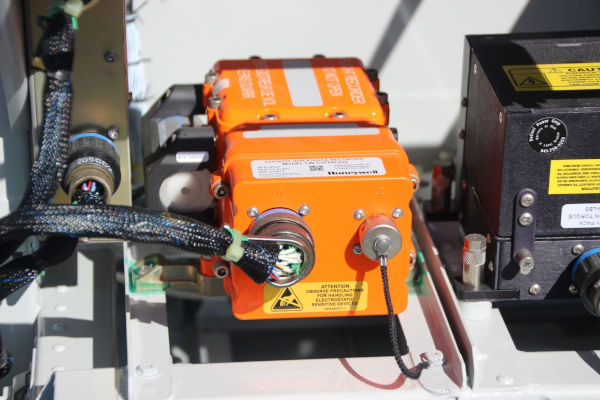

Footage has also captured dust clouds trailing AI 171 as it accelerated down the runway. Investigators will assess whether this points to loose debris, foreign object ingestion (FOD), or merely jet blast in dry conditions.

[From X]

Early speculation of a bird strike—similar to what famously brought down US Airways Flight 1549 in New York—has been downplayed. In that 2009 incident, a flock of geese struck both engines, forcing the pilots to ditch the aircraft in the Hudson River, an emergency that became known worldwide as the film “Sully: Miracle on the Hudson.” But in the AI 171 case, no birds are visible in crash footage. Experts also point out that for both engines to fail, it would typically take multiple birds hitting both sides — not a single stray bird.

Beyond immediate debris or wildlife risks, investigators will also review wake turbulence patterns left by preceding aircraft—a phenomenon where the air disturbance from one aircraft lingers and destabilizes those that follow, especially during takeoff or landing.

A notable example is Aeroflot Flight U-505, which crashed on January 16, 1987. The Yak-40—a short-range regional aircraft operating in the Soviet Union—had just lifted off from Tashkent Airport when it encountered unexpected wake turbulence from an Il-76 that had taken off barely a minute earlier. With no warning, the Yak-40 was caught in the vortex, rolled uncontrollably, and crashed fatally. The incident underscores how wake turbulence, even without prior indication, can pose a deadly threat during the critical takeoff phase.

Even seemingly minor environmental or procedural elements can set off a chain of events

Given Ahmedabad Airport’s busy operations, especially with wide-body jets like the 787, investigators will examine aircraft movement logs and air traffic sequencing to rule out any such contributing factor.

As history shows, even seemingly minor environmental or procedural elements can set off a chain of events with deadly consequences. If the investigation is thorough, no detail can be overlooked in AI 171’s case.

Air Traffic Control Communication and Radar Review

If they haven’t already, investigators will obtain the radar data and ATC recordings from Ahmedabad Airport to confirm the aircraft’s trajectory, altitude, and timeline of events.

The captain’s mayday transmission, which has been subject to public confusion, will be reviewed. Early media reports claimed the pilot also radioed "thrust not achieved…falling," implying engine trouble. Defense journalist Shiv Aroor publicly dismissed the claim.

As senior journalist Vishnu Som points out, in high-stress, low-altitude emergencies, pilots follow the mantra "Aviate, Navigate, Communicate." Their first priority is flying the aircraft—radio calls, if made, are typically short and functional.

Consider the US Airways Flight 1549 "Miracle on the Hudson" emergency. After both engines failed due to a bird strike, Air Traffic Control suggested that Captain Chesley "Sully" Sullenberger divert to the nearest airports—Teterboro or LaGuardia. Sully’s radio response was just one word: "Unable." Moments later, he transmitted, "We’re gonna be in the Hudson." No detailed explanations—his focus remained entirely on flying and keeping the aircraft under control.

[The crash landing scene from the 2016 film, Sully: Miracle on the Hudson]

Given that AI 171 was airborne for barely 30 seconds before impact, it raises serious doubts about whether the pilots had time to say anything more than a basic mayday—let alone issue a detailed technical alert like “thrust not achieved.”

ATC recordings, which are routinely captured and stored, would have already confirmed to investigators exactly what was—or wasn’t—said. So far, officials have publicly acknowledged only a standard “mayday” call.

Witness, Survivor, and Pilot Interviews

Investigators are collecting eyewitness accounts from those who saw the aircraft flying abnormally low before it crashed into a building. These statements are time-sensitive—memories fade quickly—and will be meticulously cross-checked with radar data, cockpit recordings, and wreckage analysis to establish accuracy.

[“I was scared…” Aryan Asari, the boy who recorded viral video of the horrific AI-171 plane crash]

The sole survivor, a British national of Indian origin seated in 11A, has shared chilling details. He recalled the cabin lights flickering moments before impact—a classic sign of severe electrical or hydraulic failure.

Investigators are also studying two low-resolution videos capturing the aircraft’s final moments. Despite the poor quality, early clues are emerging. Some observers believe the distinct whirring sound heard in the footage suggests activation of the Ram Air Turbine (RAT)—an emergency backup system triggered during major electrical or hydraulic failures. While the RAT itself isn’t visible, the sound, combined with the survivor’s account of flickering lights, points to a possible catastrophic onboard systems failure.

Experts say the Ram Air Turbine (RAT) on the Boeing 787 can deploy in several emergency situations—such as twin engine failure, loss of hydraulic pressure, or complete electrical failure affecting key flight instruments. It may also activate if multiple hydraulic systems fail during takeoff, landing, or approach. In some cases, the pilot can manually deploy it as well.

Only physical wreckage inspection and black box data will definitively confirm whether the RAT was deployed and why.

Central security agencies are also interviewing airport personnel, including ground crew involved in refueling and dispatch, to identify any human errors or technical lapses. According to The New Indian Express, ground staff have been asked to surrender their mobile phones for scrutiny, and CCTV footage from the airport is being reviewed for any suspicious activity.

The investigation goes beyond the crash to examine the aircraft’s recent operational history. The Indian Express reported that investigators are analysing data from Boeing’s EICAS (Engine Indicating and Crew Alerting System), which displays engine parameters and alerts crew to system configuration or faults. They are likely to cover a demanding sequence of flights: Tokyo to Paris, Paris to Delhi, and finally Delhi to Ahmedabad on June 12. Electronic Centralized Aircraft Monitoring (ECAM), the aircraft’s onboard diagnostic system, logs technical alerts, thrust fluctuations, and system faults—often revealing hidden or intermittent issues that routine checks on the ground may overlook.

Maintenance Records and Installation Checks

Air India Chairman N. Chandrasekaran has confirmed that AI 171’s right engine was replaced in March 2025, and the left engine was inspected in April. If investigators detect any irregularities, they will closely examine the installation process, as maintenance errors have led to past disasters.

One of the most cited cases is American Airlines Flight 191 in 1979, where a faulty engine reinstallation using an unapproved shortcut caused the engine to detach during takeoff, killing all 273 on board. That tragedy revealed how hidden maintenance flaws can surface with catastrophic consequences.

For AI 171, investigators will ask: Were any key components—engines, flaps, sensors—recently serviced? Was the work done properly? Could a misaligned control surface or improperly installed engine have played a role? Air India’s maintenance protocols are now under the spotlight, much like the industry-wide reckoning that followed Flight 191.

But the scrutiny goes beyond physical components. ICAO protocols require investigators to assess organisational factors—such as maintenance culture, oversight systems, and how airlines apply Minimum Equipment List (MEL) rules, which allow flights with certain non-critical components inoperative, provided safety isn’t compromised.

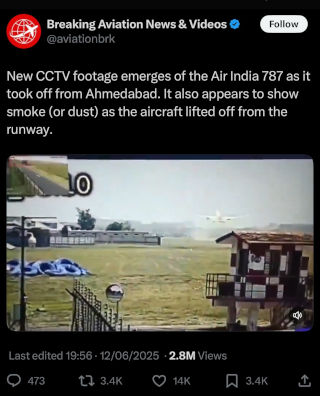

When visible systems fail, travellers begin to wonder what else might be going wrong behind the scenes

This distinction—between visible service flaws and underlying safety risks—has become a flashpoint for Air India. Akash Vatsa, a passenger on the aircraft’s previous Delhi–Ahmedabad leg, reportedly flagged issues like non-functional entertainment screens and air conditioning glitches. Such problems may seem minor, but they affect passenger perception: when visible systems fail, travellers begin to wonder what else might be going wrong behind the scenes. After a high-profile crash, these doubts become even harder to dismiss.

[From X]

However, investigators are trained to distinguish between cosmetic flaws, routine snags, and true safety concerns. Their job is to move past surface impressions and assess how the aircraft was actually maintained, operated, and cleared for flight. A key focus will be whether Air India’s Safety Management Systems (SMS) were functioning properly—or if complacency, shortcuts, or staffing pressures undermined critical safeguards.

Investigators will look far beyond cabin conditions. Multiple reports suggest that pilots are often overworked, with barely a few minutes before departure to review technical snag reports or MEL documentation. This raises concerns about whether aircraft are truly airworthy—or just cleared on paper.

While the MEL framework allows flights with certain minor defects, its effectiveness hinges on how rigorously airlines enforce it—and whether pilots feel empowered to raise concerns, especially under time pressure.

These issues point to broader questions about Air India’s safety culture. The airline has come under fire in recent months for a series of incidents, drawing passenger complaints, media attention, and regulatory scrutiny. Manish Uppal, Air India’s head of flight operations, has faced public criticism, as has the DGCA. Notably, Uppal was suspended for three months in 2020 during his tenure at AirAsia India and yet resurrected as SVP, Flight Operations, at Air India in October 2023.

In response, the DGCA ordered enhanced safety checks across Air India’s 787 fleet. Of 33 aircraft, 26 have been cleared, with the rest under inspection. Air India presents this as proof that its systems are working. But as global aviation investigations have shown, passing inspections or ticking boxes isn’t enough. Systemic failures often stem from cultural lapses, weak oversight, or repeated shortcuts.

AI 171’s investigation will probe just that. It will go beyond wreckage and black box data to examine Air India’s maintenance records, reporting culture, and internal controls—asking whether this was a tragic anomaly, or the preventable outcome of deeper structural flaws.

The 2009 crash of Air France Flight 447 revealed how a mix of technical faults, inadequate pilot training, and lapses in organizational oversight allowed manageable risks to escalate into catastrophe. It wasn’t a single failure that doomed the flight—it was the buildup of missed warnings, weak safeguards, and unresolved vulnerabilities that paved the way for disaster.

Crew History and Human Factors

Although both pilots of Air India Flight AI 171 died in the tragic crash, their training, performance history, and overall readiness are now central to the investigation.

As Reuters reported, the DGCA has formally requested detailed records for both pilots, as well as the dispatcher who cleared the flight for departure.

Captain Sumeet Sabharwal was considered highly experienced—Air India reported over 10,000 flight hours, while DGCA cited a slightly lower figure of around 8,200. For First Officer Clive Kunder, Air India listed over 3,400 hours, while DGCA records suggest approximately 1,100.

Such discrepancies are not uncommon in the immediate aftermath of a crash, as records from operators, regulators, and personal logbooks are reconciled. Investigators are now closely examining total flight hours, recent duty rosters, training records, and simulator sessions to build a verified picture of the crew’s preparedness.

With the bodies of both pilots handed over to their families, post-mortem examinations—including toxicology tests—should usually be completed. These are standard procedures after aviation fatalities and help determine whether factors like alcohol, drugs, or undiagnosed medical conditions, such as cardiac issues, may have impaired performance. However, the Kozhikode crash revealed how this process can fail. Without an aviation medical expert on the investigation team, toxicology tests were incomplete and key medical checks were missed—raising concerns that vital human factor clues were lost.

Communication breakdowns are a recurring cause in fatal aviation accidents. A 2023 study found that six of the 20 deadliest crashes since 1974 were linked to issues like misunderstood instructions, language barriers, or cockpit silence.

The Cockpit Voice Recorder (CVR) will be crucial in piecing together the flight’s final moments. Every conversation, alarm, background sound, and checklist callout will be transcribed and analyzed. But the investigation will look beyond just the final exchange—it will examine how the captain and first officer interacted from the start of the flight: their pre-flight briefing, takeoff coordination, and how they discussed abnormal scenarios such as engine failures or technical malfunctions.

Since pilots in large airlines often fly together for the first time, structured briefings are vital to establish roles and ensure coordination under pressure. These briefings can sometimes be rushed or incomplete—a factor in crashes like Comair Flight 5191, where a missed procedural step contributed to a fatal wrong-runway takeoff.

A retired Air Marshal said, “One of KLM’s most decorated captains, a legend in his airline, was in a rush to get airborne before the weather closed in and his duty hours expired. The fog was rolling in, the airport was chaotic, and everyone was on edge. His junior crew sensed something was off, but they didn’t push back hard enough. It wasn’t just miscommunication—it was hierarchy, time pressure, and human nature colliding at the worst possible moment.”

[The Tenerife Airport disaster, 1977. A KLM and a Pan Am flight collided on the runway]

Investigators will examine not just the technical accuracy of the pilots’ actions, but also behavioral cues: Were they fully alert, or showing signs of fatigue—like yawning or delayed responses? Did they maintain cockpit discipline, or were there violations of the "sterile cockpit" rule, such as non-essential chatter during critical phases like taxi, takeoff, or climb? Even subtle signs—overconfidence, tension, or casualness—can offer insight into the crew’s mindset and planning. "I’ve often had to caution pilots against discussing workplace frustrations just before takeoff," said a senior Air India training captain with over three decades of experience.

Any evidence of miscommunication or breakdowns in cockpit discipline could point to human performance issues. The Cockpit Voice Recorder (CVR) will be key in verifying whether mandatory warnings—such as takeoff configuration or engine failure alerts—sounded as expected. If such alerts are missing, it may indicate a technical malfunction or that the crew was too overwhelmed to respond.

Official duty rosters often don’t reflect reality. It’s not just about whether mandatory rest hours were scheduled—it’s whether they were actually used for rest

Experts stress that investigations must go beyond the cockpit to consider broader systemic factors that influence decision-making. A veteran Indian aviation expert, involved in several major crash investigations, noted that official duty rosters often don’t reflect reality. It’s not just about whether mandatory rest hours were scheduled—it’s whether they were actually used for rest.

“In one case I worked on, that became a crucial issue,” he said. “Some pilots from the same base were running side businesses during layovers. The co-pilot, who died in that crash, was disciplined—he used his rest time properly. But the captain? Despite checking hotel CCTV, combing through records, and interviewing people, we could never determine how he spent those hours. In the end, you can’t know what really happens behind a hotel room door.”

The AI 171 crash has renewed scrutiny of Air India’s crew rostering practices. In June 2025, the DGCA ordered the removal of three senior officials from all scheduling roles, citing repeated and serious irregularities in crew management. Though reassigned to non-operational posts, their removal has intensified concerns that systemic lapses—from crew pairing violations to poor fatigue oversight—may have placed flight crews under undue stress.

Investigators are also expected to probe broader organizational factors that could have contributed to the crash. This includes assessing the quality of Air India’s training programs, the robustness of its fatigue management systems, and any cultural or systemic issues that may have shaped decision-making in the cockpit.

Black Boxes: The Aircraft’s Silent Witnesses

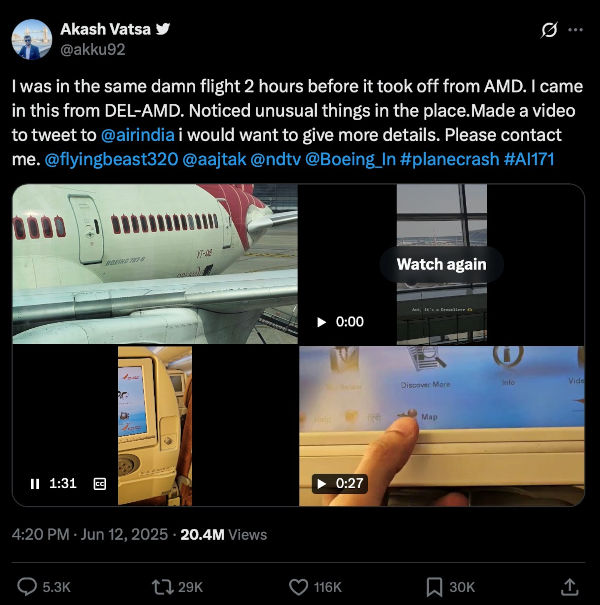

Wreckage tells only part of the story. The most definitive answers often come from the aircraft’s two black boxes—technically known on the Boeing 787 Dreamliner as Enhanced Airborne Flight Recorders (EAFRs).

[Combined Honeywell Flight Recorder in the 787. Photo by YSSYguy at English Wikipedia, CC BY-SA 4.0]

The Digital Flight Data Recorder (DFDR) on modern aircraft like the 787 captures between 1,000 and 2,000 parameters, depending on configuration. It logs data such as engine thrust, airspeed, altitude, flight controls, and electrical and hydraulic system performance—dozens of times per second—creating a precise digital record of the flight’s final moments. The Cockpit Voice Recorder (CVR) captures every sound inside the cockpit: crew conversations, alarms, ATC instructions, and even faint background noises.

Unlike older systems that separate flight data and voice recordings, the 787’s EAFRs—manufactured by Honeywell—combine both into compact, solid-state units. The aircraft also carries two identical EAFRs, each independently capable of recording cockpit audio and flight data. This redundancy offers investigators two independent sources of truth—a major advantage in catastrophic crashes.

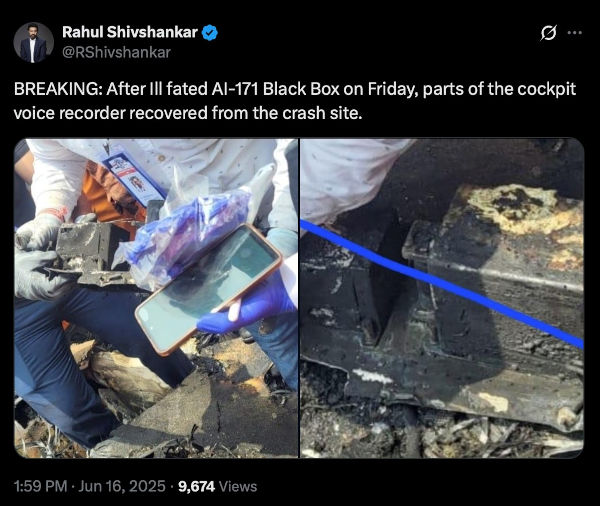

In AI 171’s case, both EAFRs were recovered. The first was found within 24 hours of the crash; the second, buried deeper in the wreckage at Meghaninagar, was retrieved on June 16.

[From X]

Modern black boxes are built to survive extreme conditions. They are engineered to withstand massive impact forces, intense fire, and prolonged submersion, ensuring vital data can still be recovered even under the harshest circumstances.

Their resilience has been proven time and again. In the 2007 Kenya Airways Flight 507 crash, the Cockpit Voice Recorder was recovered in four separate pieces—yet investigators successfully retrieved the audio, which proved crucial in understanding the accident.

Of the two recorders, the one located near the front is more vulnerable in high-impact crashes—but it also offers unique advantages. Its proximity to cockpit microphones and systems means data and audio signals travel shorter distances, allowing it to capture information a fraction of a second earlier than the tail-mounted unit. In some cases, this can reveal the final milliseconds of cockpit audio, alarms, or system status—insights that may be vital. Perhaps for this reason, investigators prioritized recovering the front recorder in AI 171’s case and successfully accessed its memory module, while data from the rear unit is still being assessed. Investigators will eventually extract the data from both the recorders to ensure dual source verification.

Beyond the black boxes, investigators are also analyzing other onboard data systems. Modern aircraft like the Boeing 787 are equipped with tools such as ACARS (Aircraft Communications Addressing and Reporting System) and AHM (Aircraft Health Monitoring), which automatically transmit performance and technical data to airline and manufacturer servers. These systems can detect early signs of hidden faults.

Today, engine data often streams live to manufacturers like Boeing and GE. “If a control inside the engine starts misbehaving, it can be flagged in real time—even mid-flight,” explained a former head of engineering at a leading Indian airline. “Though I’m not sure how advanced these features are on the 787, newer aircraft go even further.”

That said, the use of such predictive maintenance data in preventing accidents remains in its early stages—and has yet to fully deliver on its promise.

Some aircraft are also equipped with cockpit video recorders that capture instrument panels and pilot actions. If installed on AI 171, these—along with radar data, ATC audio, and maintenance logs—will be critical in reconstructing the flight’s final moments.

The insights from this data could be game-changing. Investigators will be able to confirm whether there was a thrust anomaly or a drop in engine performance during takeoff. They’ll assess if the flaps and other flight control surfaces were correctly configured, whether the landing gear retracted as expected, and if cockpit warnings were triggered in those final, critical seconds. Most importantly, they’ll be able to trace, moment by moment, how the pilots responded as the crisis unfolded.

Why Every Clue Counts: The Critical Role of Triangulation

Even the most advanced flight recorders don’t always capture the full truth. Black boxes record what the aircraft’s systems detect—but those perceptions can be fatally flawed.

The Flight Data Recorder might accurately log information—but if the inputs were wrong, the story it tells could be misleading. In such cases, the black box becomes less a record of truth and more a digital echo of a malfunctioning system

The 1996 crash of BirgenAir Flight 301 is a stark example. A blocked pitot tube—likely clogged by a wasp nest—fed the crew false airspeed readings. The black box dutifully recorded the incorrect data. To an untrained eye, the aircraft appeared to be flying normally. In reality, it was seconds from disaster.

What if something similar happened on AI 171? What if a faulty angle-of-attack sensor, airspeed probe, or engine thrust indicator fed flawed data into the system? The Flight Data Recorder might accurately log that information—but if the inputs were wrong, the story it tells could be misleading. In such cases, the black box becomes less a record of truth and more a digital echo of a malfunctioning system.

That’s why investigators rigorously cross-check every data point. They don’t accept numbers at face value—they verify them against independent sources like radar tracks, ATC communications, physical wreckage, and flight path simulations. Triangulation is the key to separating signal from noise.

Triangulation is the foundation of modern crash probes. By layering data from radar, satellite transmissions, wreckage analysis, ATC recordings, maintenance logs, and even bystander videos, investigators filter flawed signals from hard facts.

Building the Timeline: How Investigators Reconstruct Events

Crash data rarely offers neat answers. Instead, it arrives in fragmented form—thousands of raw parameters that must be tested against the aircraft’s design limits, operational logic, and real-world behavior.

It’s a painstaking, months-long process—assembling a complex puzzle where no single piece reveals the full picture

From this data mountain, investigators reconstruct the flight—second by second, system by system. Every inconsistency is scrutinized. Only when digital records, physical evidence, and external observations align does the true story of AI 171 begin to emerge. It’s a painstaking, months-long process—assembling a complex puzzle where no single piece reveals the full picture.

These insights are crucial to resolving unanswered questions that continue to fuel public speculation.

- Runway Use and Takeoff Profile: There’s ongoing confusion over whether AI 171 used the full runway at Ahmedabad. Video footage is inconclusive, and gaps have emerged in the ADS-B data. (ADS-B is a system that broadcasts an aircraft’s position, speed, and altitude, but it relies on sensors in the plane, and the data isn’t always precise—especially close to the ground.) Plus, interpretations vary. While a pilot on YouTube relying on the ADS-B data claimed that he believed the aircraft used the entire runway, the team at Pilot Debrief questioned the data and relied on additional data points, including the CCTV footage to suggest a standard threshold departure—well before the end and routine when compared with other 787 departures at the same airport. The New York Times’ analysis, reviewed by aviation experts, suggests that the plane likely extended its wing flaps and slats before takeoff, used adequate runway distance, and took-off from a typical point with a relatively normal initial ascent. This underscores why only triangulation and relying on multiple data sources—combining black box data, radar returns, ATC logs, and ground evidence—can definitively establish the actual sequence of events.

- Landing Gear Retraction: Video evidence shows the landing gear remained extended—or only partially retracted—after takeoff. While this increases drag and hampers climb, experts agree it alone wouldn’t bring down a 787. The key question: were the pilots dealing with a more urgent emergency, deprioritizing gear retraction? Triangulation will reveal whether retraction was attempted, failed due to a system fault, or wasn’t initiated at all.

- Suspected RAT Deployment: Bystander audio suggests the Ram Air Turbine (RAT)—an emergency power source—may have deployed mid-flight. But on a 787, this doesn’t automatically mean dual engine failure. The RAT can also deploy due to electrical or hydraulic failure, or be manually triggered by the crew. Only by cross-referencing flight data, cockpit recordings, and system diagnostics can investigators confirm why it deployed—and whether it signaled a deeper cascading failure.

- Flap Configuration and Stall Risk: Incorrect flap settings can severely affect lift during takeoff. However, early wreckage findings—including those cited by The Wall Street Journal—suggest the flaps and other control surfaces were properly configured. Triangulation will confirm this and clarify whether flap settings played any role in the crash.

- Engine Failure Sequence: The most debated question remains: did both engines fail? Some point to the lack of visible yaw—the side-drift typical in a single engine failure—as evidence of a dual engine failure. Others caution that poor video quality makes such analysis speculative. Moreover, the 787’s auto-rudder system dampens yaw after 60 knots, meaning absence of visible drift proves little on its own. Only triangulation will reveal whether one engine failed first, both failed simultaneously, or a different failure sequence occurred.

Only when all these fragmented data points—digital, physical, and observational—are layered together, tested, and challenged, will investigators develop a reliable, comprehensive reconstruction of AI 171’s final moments.

(Next: Part Three: How the investigators are likely to complete the crucial root cause analysis. Read it here)